How Do I Decide Which Size Mesh Screen to Use

Carefully mark the sieve for 1 inch using a permanent marker and scale. Two scales are used to classify particle sizes.

How To Select The Right Mesh For Screen Printing Norcal Sps

How do I know which mesh size to get.

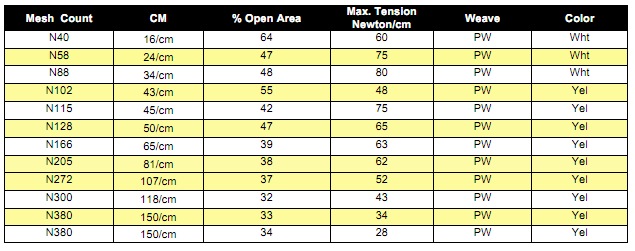

. For instance a 110 mesh screen has 110 threads crossing per square inch. The paper cut out will help you keep track of the line of openings as. For example a number 4 mesh will have 4 openings per square inch.

Since each type of mesh has a different life span you can choose the best option for you based upon how long you intend on using your structure. For example a 12 mesh screen means that there 12 openings across one inch. It is a very simple method to determine the mesh size of any sieve or screen.

Spline is measured by diameter which determines the thickness of spline youll need to secure your screen to the frame. D 25400 1 n d where D opening size in micron n mesh count in number of wires per inch 1 per inch d wire diameter inches. A -6 mesh powder contains particles that pass through a 6 mesh screen.

Figuring out the mesh number is simple. Step 2 Measure a 1-inch-by-1-inch square section of the mesh and mark it with a permanent marker beginning from the center of one of the wires. Screen mesh size is determined by the number of openings per square inch of mesh.

Method of identifying mesh which is a measure of how many strands contained within one linear inch of the mesh. Generally US Mesh is measured using screens down to a 325 mesh 325 openings in one square inch. Hey guys I would like to print on clothes with plastisol and water based ink.

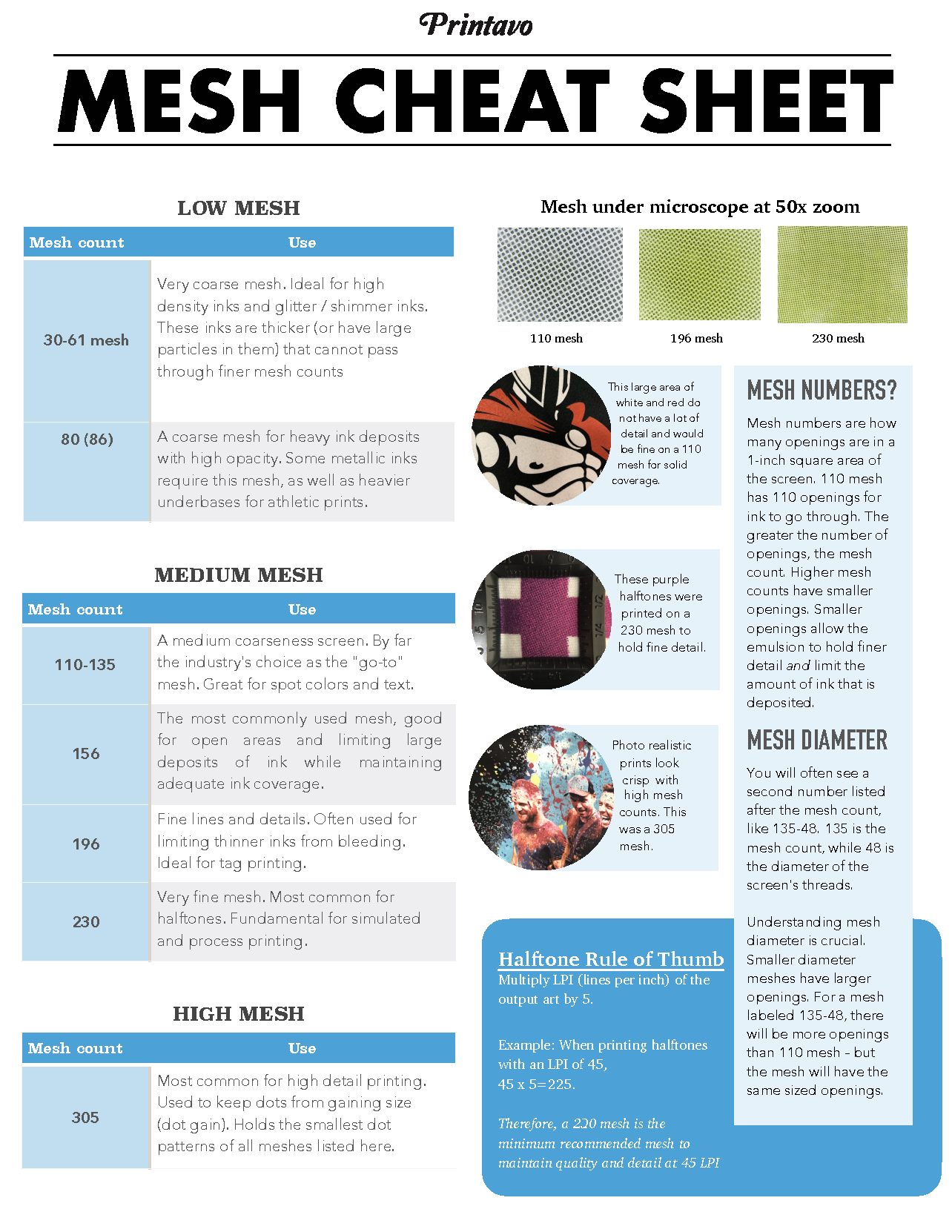

How to decide mesh element size and growth rate. 200 LPI mesh will have smaller hole size openings compared to 100 LPI because there are twice as many lines of fiber per inch. How to decide which mesh count you should useorange screen printing mesh screen printing mesh t120 43 screen printing mesh screen printing mesh saier 180m screen printing mesh--Eybetters.

Air Flow - the number one feature most look for in a screen mesh. The typical particle sizes used in GC are. MICRON VS LPI Mesh sizing The US and some other countries use the lines per inch or LPI.

For a single layer screen cloth with a known mesh count and wire diameter the opening size can be calculated as follows. Sometimes the mesh size of a product in noted with either a minus - or plus sign. For screen doors standard 18 x 16 mesh with a 011 diameter wire thickness is typically recommended to keep out common insects.

All you do is count the number of openings in one linear inch of screen. Mesh size is fairly straightforward. A number 16 mesh will have 16 openings per square inch.

Log in or sign. The number of holes in one linear inch is known as the mesh. How do I decide the size of the mesh basket to order.

6080 mesh or 250177 μm. Mesh size usually is referring to the mesh number a US measurement standard and its relationship to the size of the openings in the mesh and thus the size of particles that can pass through these openings. Step 1 Lay the screen mesh on a flat surface that allows light to flow through the mesh openings.

Please how do i determine the best size of mesh to use in FLUENT for the simulation of an inclined oil-water flow system Any Expert on CFD simulation using ANSYS Computational Fluid Mechanics. A 120 mesh screen means the openings are much smaller and that there are 120 openings per inch. The higher the mesh count the finer the threads and holes are in the screen.

A powders mesh size can at times be somewhat confusing. December 2020 in Preprocessing. What does mesh size mean.

These signs indicate that the particles are either all smaller than -. The first thing you will want to consider when choosing the best mesh for you and your screen enclosure or pool cage is the length of time you are planning on staying at this home. Wire mesh is designated by Mesh Number number of wires per inch and Wire Diameter the diameter of each wireA higher mesh number means more wires to the inch a.

The size of the mesh has a lot to do with how detailed your image is and how thick the ink you are using is. The mesh size is determined by counting the number of openings it has per square inch. Mesh size is measured by how many threads of mesh there are crossing per square inch.

This will minimize counting mistakes. It measures the number of openings in the mesh that make up one linear inch. How do I know which mesh size I have to use.

Sieves and screens are usually used for larger particle sized materials greater than 44 micron 325 Mesh. The spline itself is flexible and able to be. Measurement should be started from the center of the wire to make it more accurate.

Tighter weave mesh like solar and insect screen will not give you the same air flow volume as the standard fiberglass or aluminum screen. US Sieve Series and Tyler Mesh Size. If maximum air flow is what you are looking for choose a charcoal or grey fiberglass or traditional fiberglass.

Count the number the holes in this area. If the column uses a support the particle size of the support is generally expressed in terms of screen openings since screens or sieves are normally used to prepare them. The charts below can show you which type of spline you should use for your screen.

Wire Mesh Size Designation. 80100 mesh or 177149 μm and 100120 mesh or 149125 μm.

How To Choose The Right Screen Printing Mesh Size

0 Response to "How Do I Decide Which Size Mesh Screen to Use"

Post a Comment